Material Description:

Lithium iron phosphate electrode materials are mainly used in various lithium-ion batteries. Since NTT in Japan first revealed the olivine structure of AyMPO4 (A is an alkali metal, M is a combination of CoFe: LiFeCoPO4) as a positive electrode material for lithium batteries in 1996, a research group led by John B. Goodenough from Texas State University in the United States also reported the reversible migration and extraction of lithium from LiFePO4 in 1997.

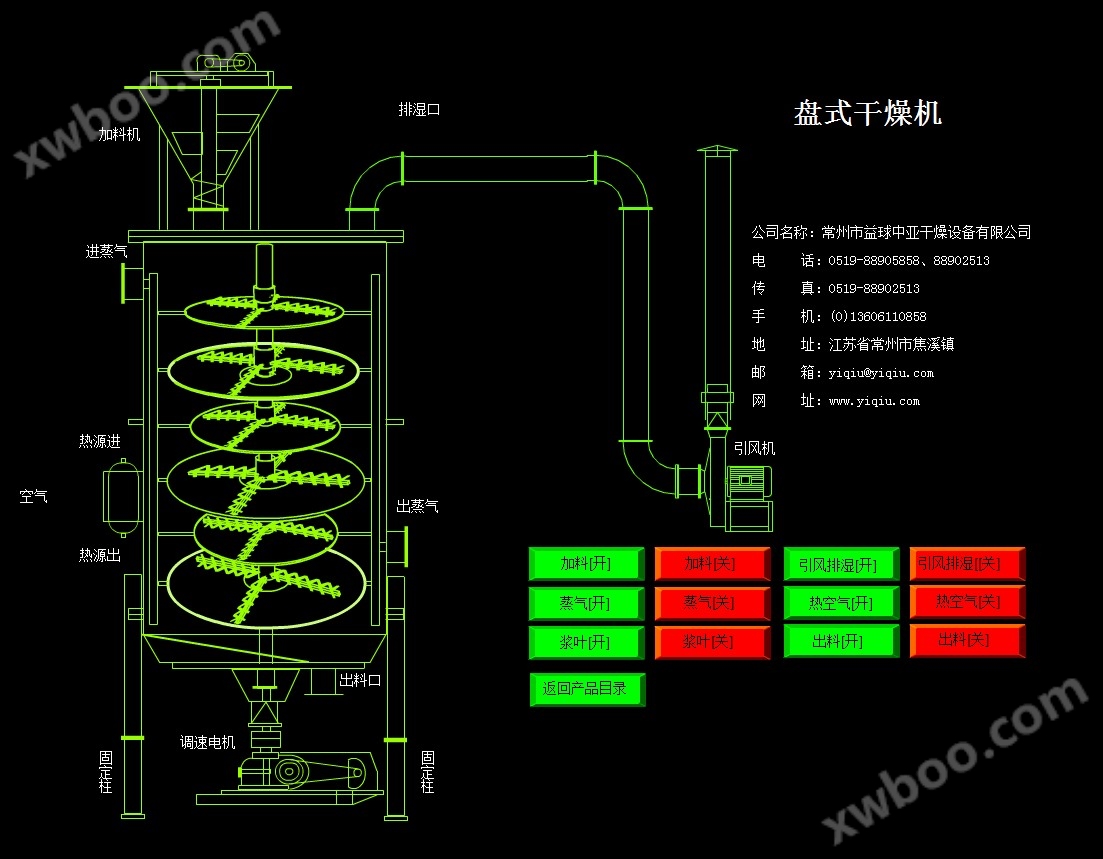

Product Name: PLG Series Disc Continuous Drying Machine

Overview:

The disc continuous dryer is an efficient conductive continuous drying equipment. Its unique structure and working principle determine that it has the characteristics of high thermal efficiency, low energy consumption, small footprint, simple configuration, convenient operation and control, and good operating environment. Widely applicable to drying operations in industries such as chemical, pharmaceutical, pesticide, food, feed, and agricultural and sideline product processing. Highly praised in practical applications across various industries. It can be divided into three types: atmospheric pressure, sealed, and vacuum; Various specifications such as 1200, 1500, 2200, 3000, etc; A (carbon steel), B (stainless steel for the contact material part), and C are made of three materials (stainless steel for the steam pipeline, main shaft, and support, and stainless steel for the cylinder and top cover lining) on the basis of B, with a drying area of 4-180m2. There are hundreds of models of series products available, and supporting auxiliary equipment can be provided to meet the drying needs of users for various materials.

characteristic:

(1) Easy regulation and strong applicability

By adjusting the thickness of the material layer, spindle speed, number of rake arms, rake blade type and size, the drying process can be optimized.

2. Each layer of the drying tray can be filled with a hot or cold medium to heat or cool the material, ensuring uniform heating and accurate temperature control.

3. The residence time of materials can be precisely adjusted.

4. The material has a single flow direction, no backmixing phenomenon, uniform drying, stable quality, and does not require further mixing.

(2) Simple and easy to operate

The operation of driving and parking the dryer is very simple.

After stopping the feeding, the rake blades that transport the material can quickly empty the material inside the dryer.

3. Through the special large-sized inspection door mirror, careful cleaning and observation can be carried out inside the equipment.

(3) Low energy consumption

1. The material layer is very thin, the spindle speed is low, and the material conveying system requires less power and consumes less electricity.

2. Drying is carried out using conductive heat, which has high thermal efficiency and low energy consumption.

(4) Good operating environment, recyclable solvents, and dust emissions meet requirements

1. Atmospheric pressure type: Due to the low airflow velocity and low humidity distribution inside the equipment, it is difficult for dust to float to the top of the equipment, so the exhaust gas discharged from the top humidity outlet contains almost no dust.

2. Sealed type: equipped with a solvent recovery device, which can easily recover organic solvents in wet gases. The solvent recovery device is simple and has a high recovery rate. For flammable, explosive, toxic, and easily oxidizable materials, nitrogen can be used as a carrier gas for closed-loop circulation to ensure safe operation. Specially suitable for drying flammable, explosive, and toxic materials.

3. Vacuum type: A disc dryer operated in a vacuum state, particularly suitable for drying heat sensitive materials.

(5) Easy installation and small footprint

1. The dryer is shipped as a whole and only needs to be lifted into place for easy installation and positioning.

Due to the layered arrangement and vertical installation of the drying tray, even if the drying area is large, the footprint is also very small.

Explanation: In order to prevent improper competition, detailed technical information cannot be disclosed. Please call for consultation. This device can be customized non-standard,We are one familySpecializing in drying equipmentofEnterprises engaged in research, development, design, and manufacturing have rich experience in non-standard production. Our company has prototypes available all year round, and you can bring materials to test them,weSincerely cooperate with new and old customers at home and abroad, and create brilliance together in the new century!